% all within approximately 20 hours, dependant on the waste being composted and its moisture/water content.

1) All organic/ food waste – 85-90%

2) Garden Waste 60-70%

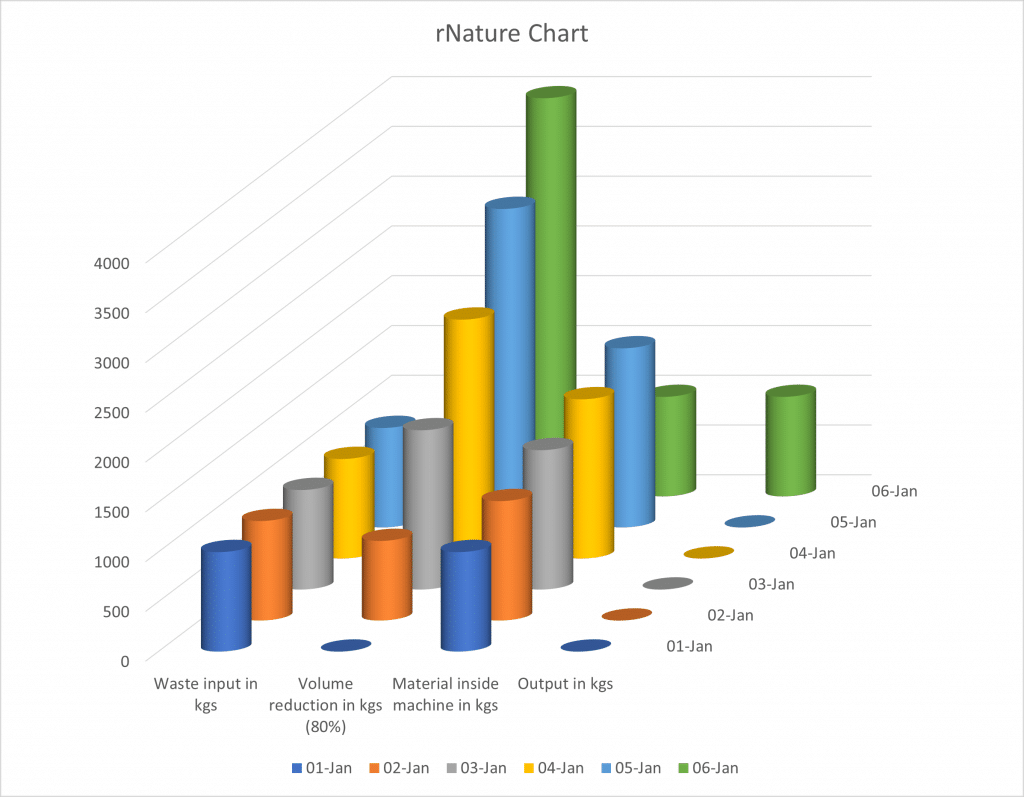

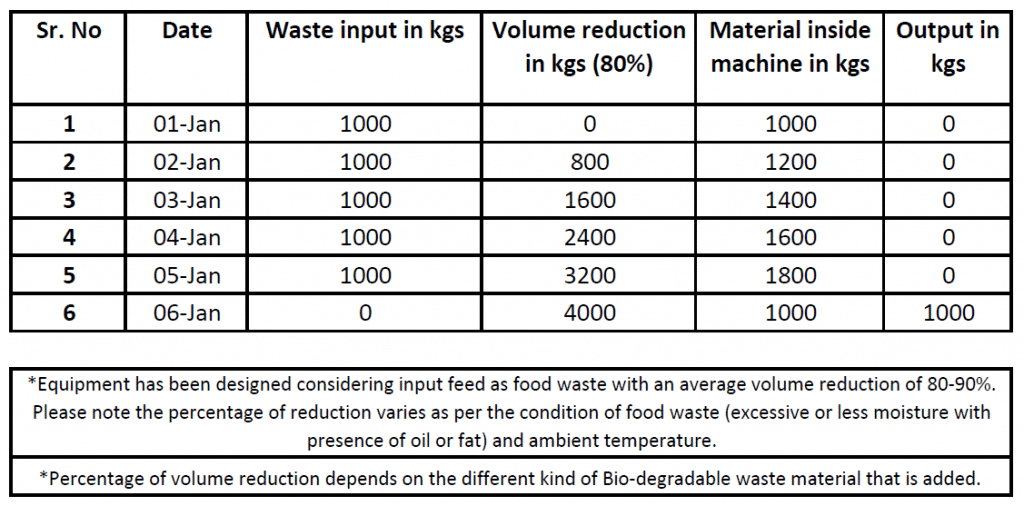

3) The machines are all fully automatic, each day over a 5 day duration, its kg capacity equivalent can be added, without emptying any compost.

So for a **rN1000, 7000kgs (1000kgs/ day) can be added for 5days.

The supplied mother enzyme and saw dust are added at the time of commissioning:

– The red beacon installed on top of the machine will be activated along with an annunciation sound when the process is completed and indication will be shown on the touch screen panel, reading ‘Process Complete’

-for successful ongoing workings of this technology, if working with organic waste, it is best to ensure 100% organic waste is fed regularly into the machine, say every morning and evening

– a minimum of 1m all around the machine

If the food waste being processed, contains a “

very high amount of liquid in the form of moisture/water or oil, including sludge in livestock abattoirs,” then our pre-treatment process will be required. This process further helps in volume reduction of the waste.

After going through this process, the end product is then loaded into our rN composting machines as normal.

The process of decomposition within the machine is a continuous process 24/7.

During the process odour is always generated. It’s only the extremity of the odour that varies as per the status of decomposition within the vessel, wherein at times it may be very high and very low during the process.

As and when the input waste reaches its process completion, the odour reduces along with it.

The final product does not have a pungent or a putrid odour to it.

Our rNature technology incorporates an Aerobic process. In which the complete process is carried out without restricting the supply of oxygen into our machine chambers. Therefore it enhances the process and because there is continuous supply of oxygen, there is little to no methane produced within our RNature automatic composting machines.

Furthermore, our technology does not add to the vast build-up of greenhouse gases in the atmosphere. Providing further proof of our technology being very sustainable and protecting the environment.

Whereas other food waste composters use a different way of processing food waste via an Anaerobic process, in which the complete process is carried in an air tight enclosed chamber, whereby the supply of oxygen is cut-off; this is the reason why methane is produced while processing this food waste.